Description

- Programmable analysis sequences with added automation takes work off your hands

- Automated loop injectors, pulse titration and temperature-programmed analysis minimize human interference

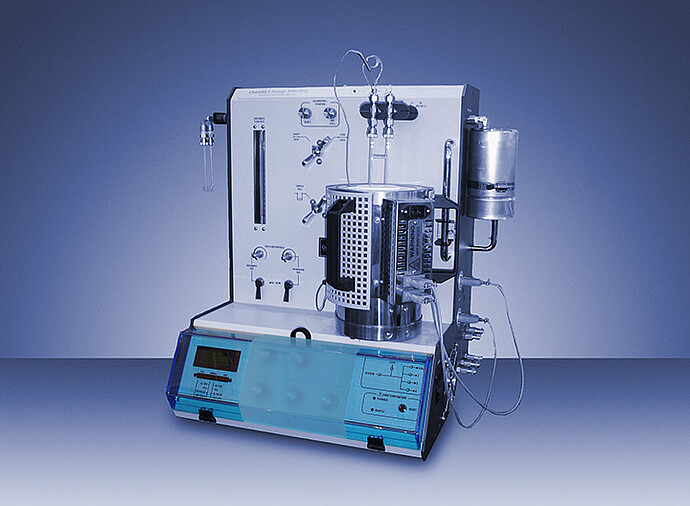

- Minimal space required

ChemBET Pulsar combines affordability and automation in a compact benchtop catalyst characterization unit. Programmable analysis sequences combined with an automatic loop injector, gas switching, and furnace temperature ramping enable easy pulse titration and temperature-programmed analyses with minimal user intervention. An advanced data reduction package including peak deconvolution, comparable to high-end catalyst characterization units, comes as a standard.

| Sample stations | 1 analysis and 1 dedicated outgassing |

| Typical samples size | 0.1 g to 1.0 g |

| Temperature range | Ambient to 1100 °C |

| Temperature ramp rate | 1 °C/min to 50 °C/min |

| Furnace cooling | Built-in fan |

| Gas inputs | 4 analysis and 1 calibration |

| Sample cell | Quartz U-tube for high-temperature chemisorption |

| Primary detector | Oxidation- and ammonia-resistant (W/Re) 2-filament TCD |

| Dimensions (W x H x D) | 45.2 cm x 63 cm x 41.4 cm (18 in x 25 in x 16 in) |

| Standard capabilities | Temperature Programmed Desorption (TPD) Temperature Programmed Reduction (TPR) Temperature Programmed Oxidation (TPO) Temperature Programmed Reaction (TPRx) Catalyst Treatment Flow BET Surface Area Pulse Titration Pulse Calibration |